Alloy Enterprises Extends Direct Liquid Cooling Across the Blade, Eliminating the 100 kW Peripheral Heat Bottleneck

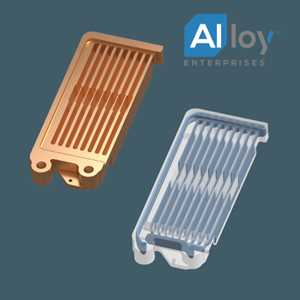

BOSTON, Nov. 05, 2025 (GLOBE NEWSWIRE) -- Alloy Enterprises today announced a breakthrough in data center cooling: single-piece, leak-tight cold plates that extend direct liquid cooling (DLC) across the blade, including DIMMs, NICs, and QSFPs. Built using the company’s patented Stack Forging™ process, the new design enables full-blade liquid cooling for the first time, eliminating the emerging 100 kW peripheral heat bottleneck in next-generation 600 kW server racks.

As rack and power densities continue to climb, the thermal balance inside high-performance servers has shifted. Historically, GPUs consumed about 80% of a blade’s total power, leaving the remaining 20%, from DIMMs, NICs, QSFPs, and other peripherals, manageable with air cooling.

“Direct liquid cooling no longer stops at the GPU,” said Dr. Ali Forsyth, CEO and co-founder of Alloy Enterprises. “What used to be the ‘other 20%’ of blade power is quickly becoming a major heat source that air cooling simply can’t handle. Our single-piece cold plates extend efficient, reliable liquid cooling to every component, enabling true 100% coverage at rack scale.”

In today’s NVIDIA NVL72 rack (120–140 kW), peripherals account for 24–28 kW, which remains within airflow limits. Upcoming 600 kW-class systems, such as NVIDIA’s Kyber-based Rubin platform, will produce over 100 kW of heat in just the peripherals. This is 4x the total thermal load of current GPU racks and significantly exceeds airflow cooling capabilities. Without alternative and effective cooling, these peripherals create a bottleneck within the rack, negatively impacting compute availability and revenue for data center operators.

Alloy’s single-piece cold plates offer the cooling needed for optimal compute, combining internal microgeometries with monolithic construction, and enabling efficient, high-pressure, leak-free cooling where traditional brazed or soldered assemblies cannot survive. Rated to 2,000 psi without deformation, the plates maintain structural integrity under extreme flow rates. A library of plug-and-play microgeometries allows Alloy to target heat extraction for each peripheral, optimizing performance for the power and space constraints of next-generation server blades.

“As rack power climbs toward 600 kW, the industry must rethink how it manages every watt of heat,” continues Dr. Forsyth. “Stack Forging from Alloy enables new design freedoms for direct liquid cooling across the blade, and our single-piece construction addresses reliability risks inherent in incumbent solutions that include brazing and soldering.”

Alloy’s Component-Specific Benefits

-

DIMMs

- Dual-sided cooling supports >40 W modules, meeting next-gen JEDEC specs.

- Serviceable design allows replacement without draining the loop.

- Eliminates up to 32 solder joints, improving reliability in dense arrays.

-

QSFPs

- Handles up to 50 W per port for 800 G and 1.6 T optical modules.

- Enables high-I/O density with dozens of ports per blade.

- Compact, single-piece design integrates with standard form factors—no bulky manifolds required.

-

NICs & Specialty ASICs

- Cools devices with heat flux densities exceeding today’s top GPUs.

- Low-profile, monolithic plates maintain uniform cooling and mechanical stability.

- Fits within tight board geometries, maximizing density and performance.

To dive deeper into this, join Alloy’s upcoming webinar, Unlocking Full-Blade Liquid Cooling with Single-Piece Peripheral Cold Plates, on November 6, 2025, at 8:00 AM PT / 11:00 AM ET, or visit Booth #5410 at SC25 in St. Louis, November 16–21.

About Alloy Enterprises

Alloy Enterprises delivers high-performance thermal management components designed and manufactured in the U.S. Our patented Stack Forging™ process creates leak-tight, single-piece components with embedded microgeometries. These enable maximum heat transfer, reduced pressure drop by up to 4×, and improved thermal resistance by over 35%, dramatically lowering pumping power and energy use. Our solutions support a wide range of applications, including GPUs, CPUs, memory modules, NICs, power electronics, and semiconductor tools. Now shipping to leading data center, industrial, and military customers.

For more information, visit www.alloyenterprises.co.

Media Contact

Samantha Lindsay, Alloy Enterprises

sam.lindsay@alloyenterprises.co

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/20bd0964-a779-4864-8265-11ef8c97977f

Alloy Enterprises Delivers Industry-First Direct Liquid Cooling Across the Blade

Using its patented Stack Forging™ process, Alloy Enterprises extends direct liquid cooling across the blade with single-piece, leak-proof cold plates. The breakthrough eliminates the emerging 100 kW peripheral heat bottleneck in next-generation data center racks.

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.